About manufacturing at Iwachu

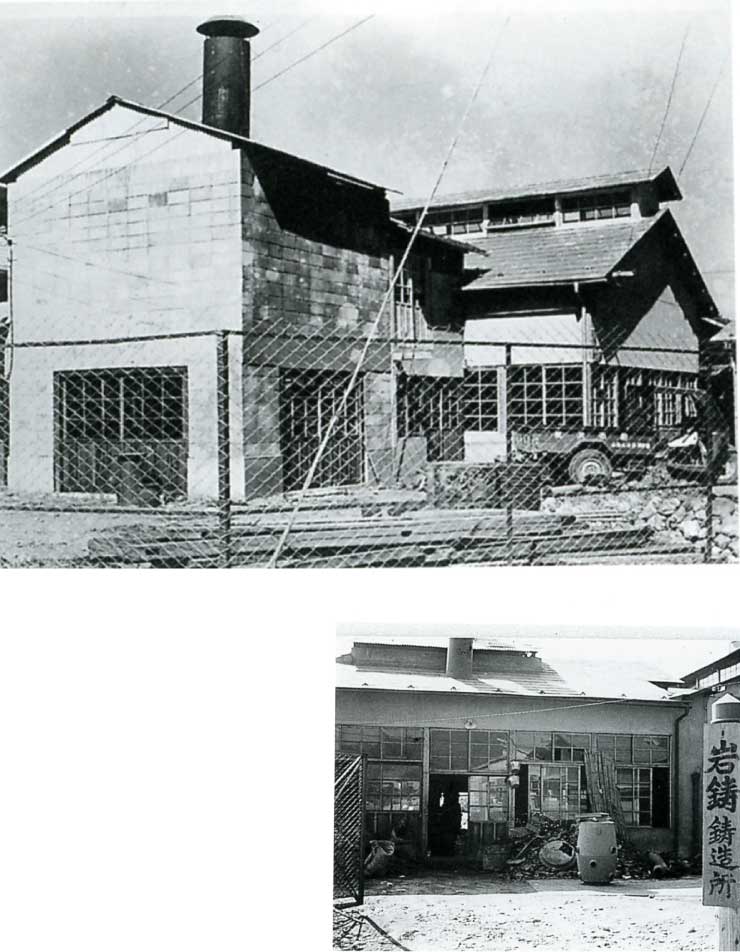

A story of rock casting that began in a small ironware workshop in the city.

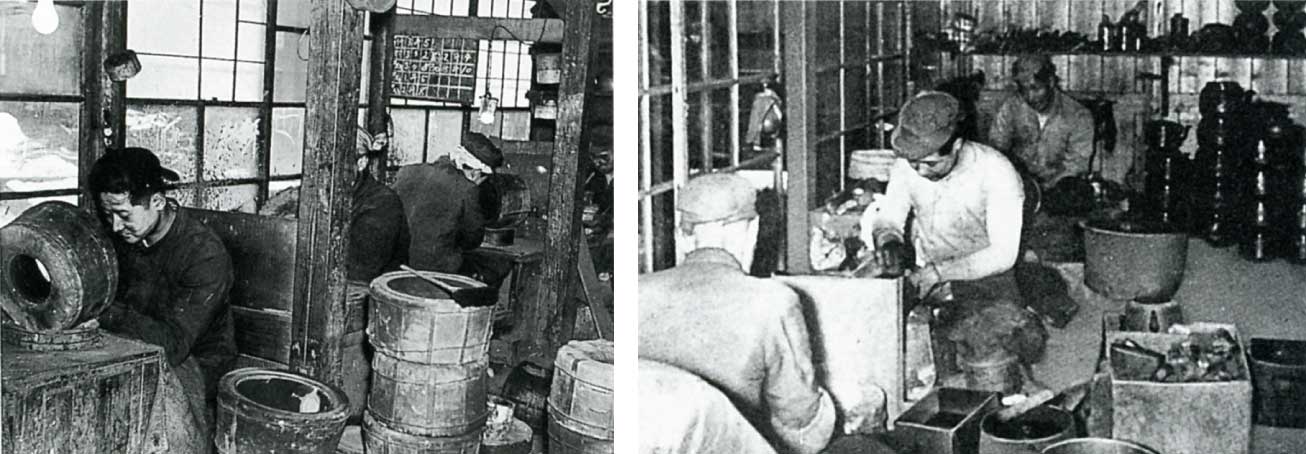

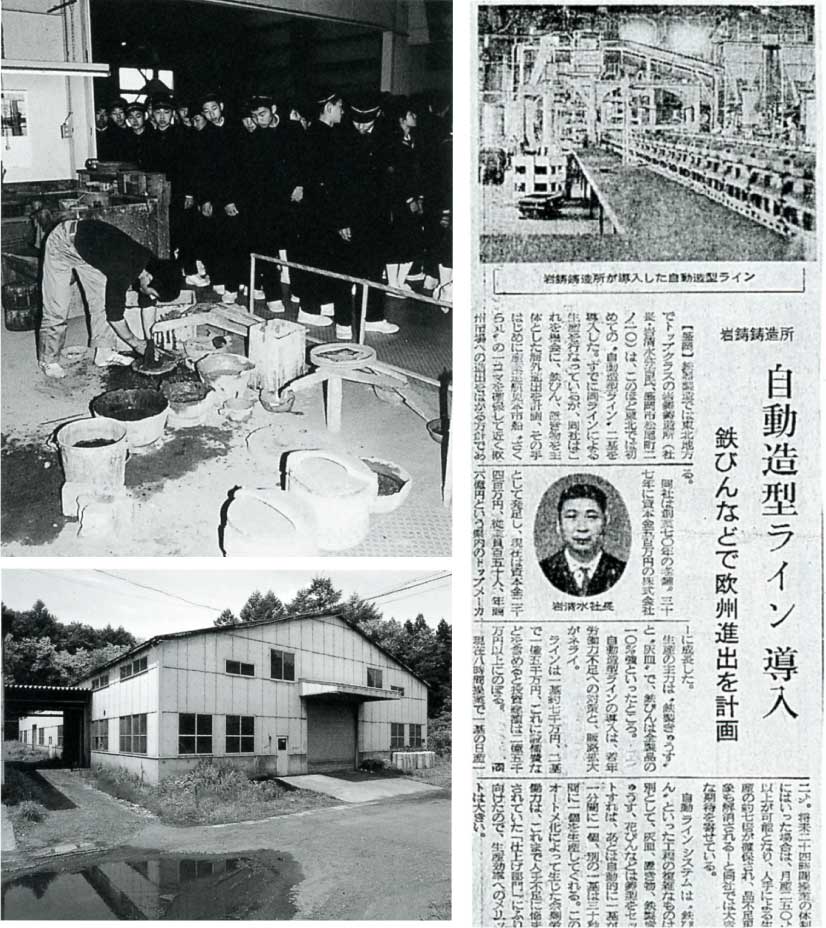

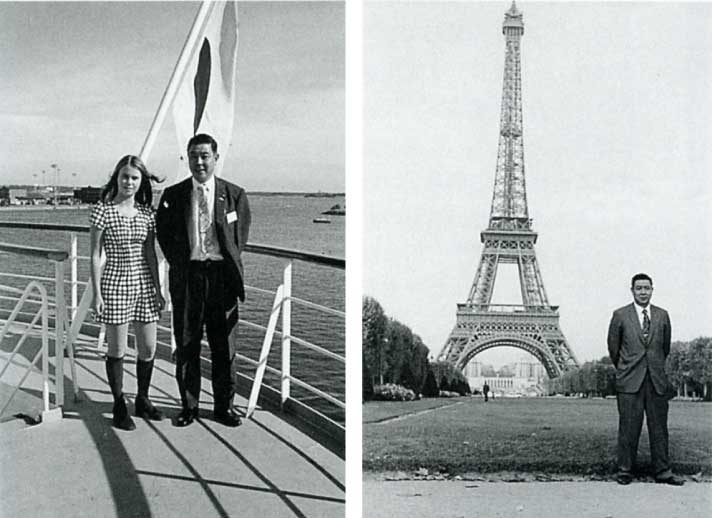

During the Meiji and Taisho eras, when the fame of Nambu tekki resonated throughout the country, there were many trials, including the suspension of production due to war and changes in lifestyle.

However, because of the solid foundation of tradition,

We were able to keep trying.